14/11/2017

Updated Guidance to LOLER Testing

In line with the ISO 10535 requirement that every inspection should include a working load test of one lifting cycle, we would always recommend that testing be performed with dead weights whenever possible, to closely simulate the actual operating conditions of the hoist when in normal use.

However, we understand that it is not always possible to use dead weights this may be due to limitations in transportation, accessibility or manual handling restrictions. In circumstances such as these the use of alternative test procedures utilising spring balances or load cells can be adopted.

When undertaking these alternative test procedures care must always be taken with care to ensure the load is evenly distributed across all castors on the hoist base, and that the testing equipment is never attached directly to the base itself due to the risks of damage.

To simulate as closely as possible a complete lifting cycle, we would recommend that a minimum of 5 readings are taken at regular intervals across the full range of lifting arm movements to gain an accurate and more reliable representation.

The relevant sections of industry & regulatory recommendations taken in making this decision are as follows:

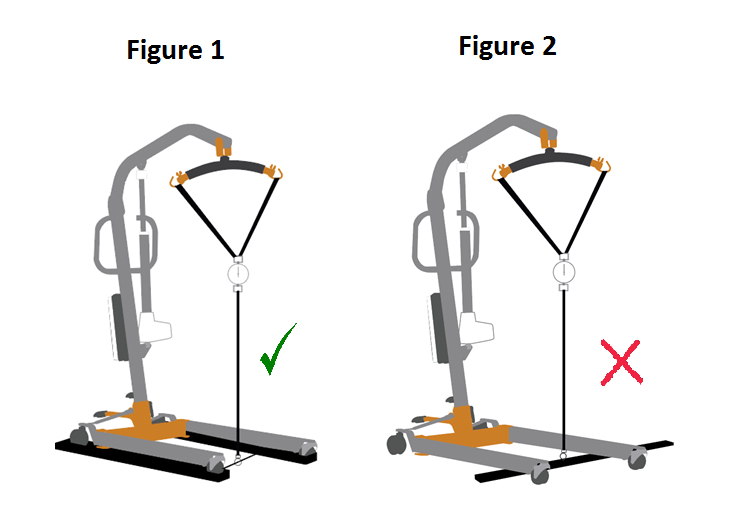

Below is examples of how this should be undertaken (Figure 1), it is vital that when taking a reading that the load is distributed evenly across all four castors. This can be achieved by fitting the Hoist onto a board or two steel channels which span the length of the Hoist Base and support all 4 castor wheels. When testing, the load is then applied through all 4 casters and the base of the hoist evenly – See Figure 1

ISO 10535 “Hoists for the transfer of disabled persons – requirement & test methods”:

Periodic Inspection.

B.1 Periodic Inspection of the hoist should be undertaken at the time intervals stated by the manufacturer, but at least once a year. By periodic inspection is meant a visual examination (particularly of the hoist’s load bearing structure and lifting mechanism with attachments, brakes, controls, safety devices and person-support devices) and whatever function tests and maintenance measures may be required, e.g. adjustment of brakes, tightening of fasteners.

Every inspection should include a working load test of one (1) lifting cycle with the maximum load.